Inductor and chokes

GT Electronic India is a well experienced manufacturer of customized toroidal chokes, high current chokes, output chokes, EMI filters, power inductors and power supply filtering chokes for various applications.

Features and Versions (based on customer`s application):

- Toroidal or EI

- Iron powder and Si-Fe ferrites

- Mounting can be horizontal or vertical

- Manufacturing with mounting/base plate or encapsulated with potting/vacuum potting

- Manufacturing in customized terminals like SMD PIN, through hole PIN or flying leads with crimp/connectors

- Construction according to EN 61558-1, UL insulation system for class F (GT owned), RoHS and REACH conformity

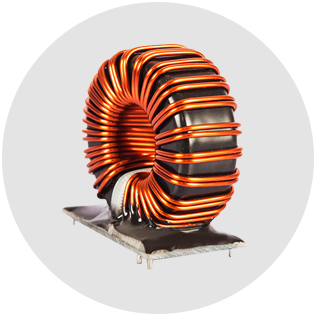

Common Mode Choke

Common Mode Choke

The CMC chokes (two /more coils are wound on a single core) are used for prevention of electromagnetic interference (EMI) and radio frequency interference (RFI) from power supply lines and for prevention of malfunctioning of electronic equipment.

Enquiry

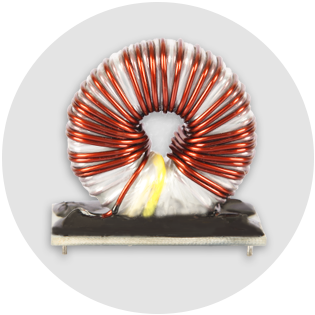

Current Compensated Suppression Choke

Current Compensated Suppression Choke

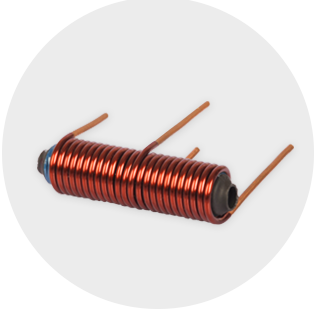

Rod Core / Drum Core Inductor

Rod Core / Drum Core Inductor Power Factor Correction Chokes (PFC)

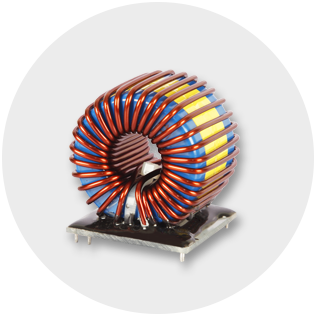

Power Factor Correction Chokes (PFC)

Storage Chokes

Storage Chokes